The use of alternative raw materials and fuels in the production of cement is a great example of industrial symbiosis and provides a solution with considerable benefits to address the problem of waste management.

It is a critical aspect in the circular economy model, which fully promotes the reduction of waste and the reuse, repair, and recovery of materials and energy.

Use of alternative raw materials.

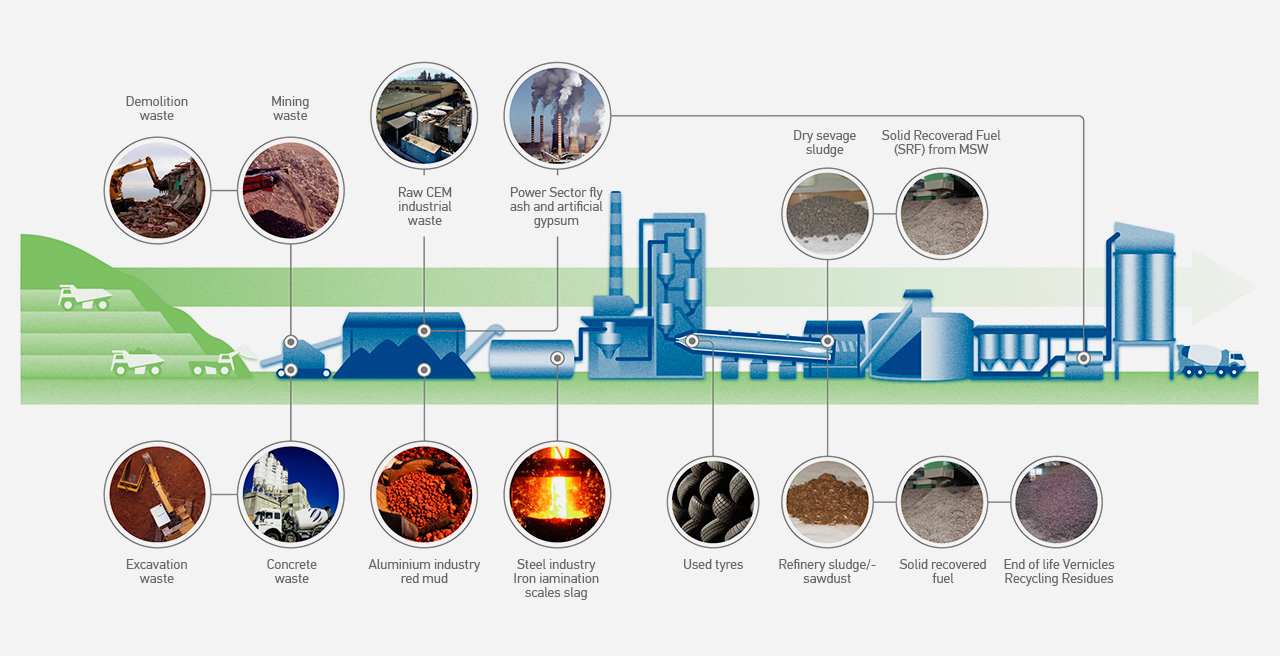

The use of alternative raw materials contributes towards saving natural, non-renewable resources. They are mostly by-products and waste of other sectors, such as fly ash, bottom ash of thermoelectric power plants, blast furnace slag, iron lamination scales, glass recycling waste, dredging spoils, demolition waste and concrete production waste.

In recent years, we have developed and are implementing an innovative solution: we use recycled excess concrete and demolition waste in the production of cement, sending a clear message that buildings and concrete are recyclable. In other European countries, these materials are only used as aggregates in the construction of roads.

Concrete returns from the units of our subsidiary INTERBETON, which would otherwise be sent to landfills, are already being used as alternative raw materials in the production of cement.

Use of alternative fuels.

This technology, complementary and not competitive to recycling, utilizes in the clinker production kiln

- both the waste that would otherwise have to be buried, thus recovering the energy contained in them,

- and materials that are incorporated in the mineralogical structure of clinker in non-water-leachable form, thus avoiding the generation of waste or residues.

Alternative fuels generally contain a high percentage of biomass, which brings about a reduction of CO₂ emissions.

They include: secondary refuse derived fuel (SRF, RDF), dried sewage sludge from waste water treatment plants, petroleum residues mixed with sawdust, used oils and lubricants, packaging recycling residues, paper, wood, sawdust, fabric, biomass from agricultural and forest residues, animal feed, and organic waste, end-of-life tyres, etc.

The use of alternative fuels adheres to specific high standards aimed at safeguarding health and safety, as well as complying with environmental limits and the quality specifications of our products.

Alternative fuels are subject to controls both at production and upon delivery to the cement plants.